Current location:Home > oil seal tcn >

oil seal tcn

2025-08-15 18:11

2025-08-15 17:28

2025-08-15 17:21

2025-08-15 16:53

Another factor that can contribute to oil seal failure is contamination. Around 47% of oil seals fail due to contamination by dirt, debris, or other particles. This can cause the seal to wear out quickly and lose its effectiveness. Regularly cleaning and inspecting the seals can help prevent contamination and prolong their lifespan

25 47 7 oil seal.

25 47 7 oil seal.

...

2025-08-15 16:41

2025-08-15 16:28

2025-08-15 16:14

2025-08-15 16:13

2025-08-15 16:11

2025-08-15 16:02

Latest articles

Once you have your seal kit, it is time to start the repair process. Start by lowering the jack all the way down and removing the oil filler plug. Drain out any remaining oil and remove the ram from the jack. Carefully disassemble the jack, taking care to keep track of where each part goes.

3 ton hydraulic jack seal kit

Maintaining these seals is equally important. Regular inspections should be conducted to check for signs of wear or damage. If the seal shows any cracks, tears, or if the lips are worn down, it's time for a replacement If the seal shows any cracks, tears, or if the lips are worn down, it's time for a replacement If the seal shows any cracks, tears, or if the lips are worn down, it's time for a replacement If the seal shows any cracks, tears, or if the lips are worn down, it's time for a replacement

If the seal shows any cracks, tears, or if the lips are worn down, it's time for a replacement If the seal shows any cracks, tears, or if the lips are worn down, it's time for a replacement 31x43x10 5 oil seal. Neglecting this can lead to oil leaks, which not only waste valuable resources but also pose environmental risks and increase maintenance costs.

31x43x10 5 oil seal. Neglecting this can lead to oil leaks, which not only waste valuable resources but also pose environmental risks and increase maintenance costs.

If the seal shows any cracks, tears, or if the lips are worn down, it's time for a replacement If the seal shows any cracks, tears, or if the lips are worn down, it's time for a replacement

If the seal shows any cracks, tears, or if the lips are worn down, it's time for a replacement If the seal shows any cracks, tears, or if the lips are worn down, it's time for a replacement 31x43x10 5 oil seal. Neglecting this can lead to oil leaks, which not only waste valuable resources but also pose environmental risks and increase maintenance costs.

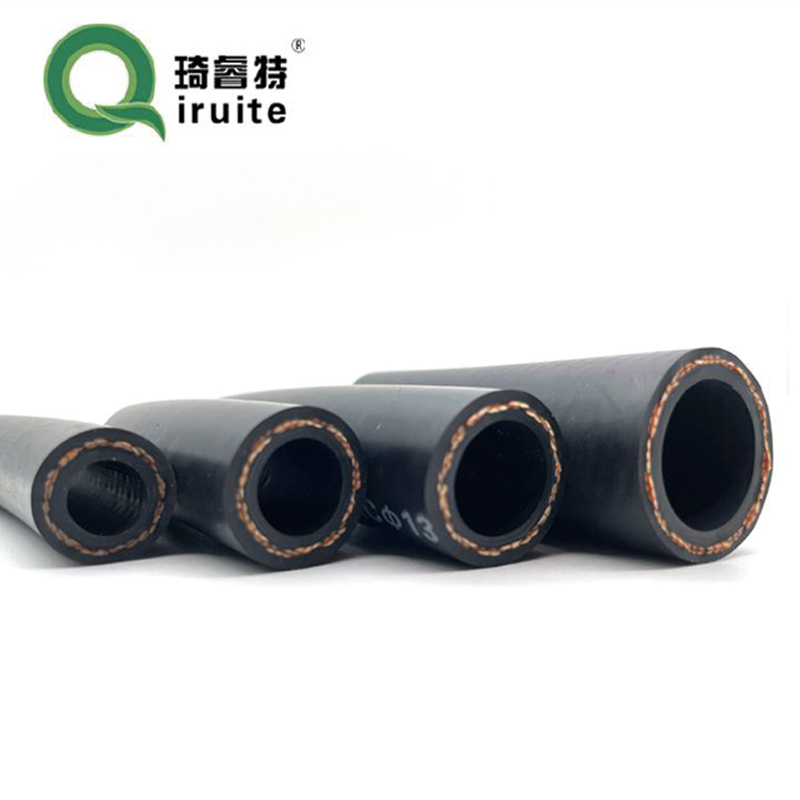

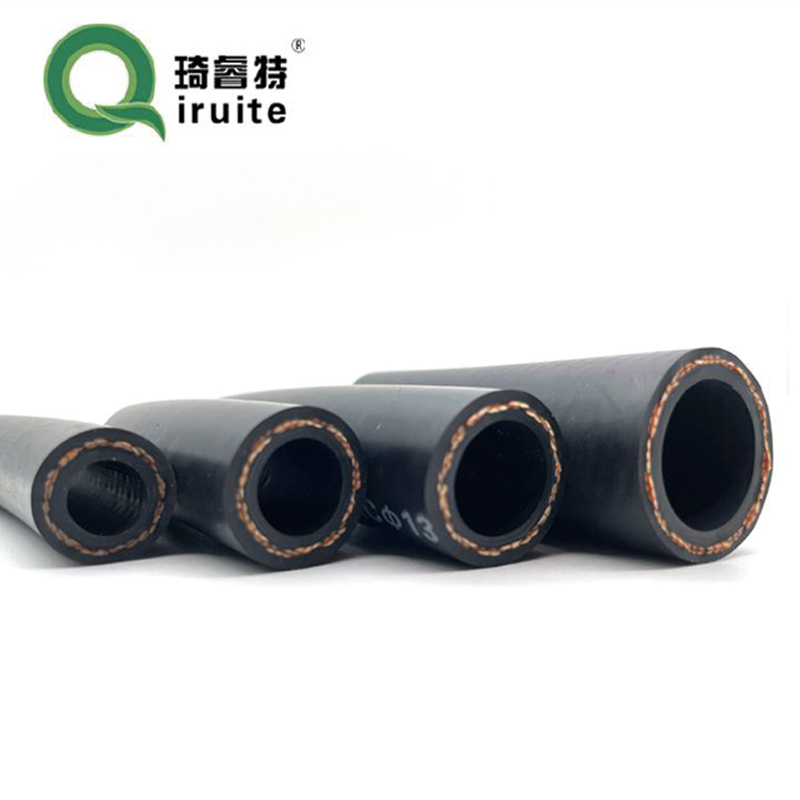

31x43x10 5 oil seal. Neglecting this can lead to oil leaks, which not only waste valuable resources but also pose environmental risks and increase maintenance costs.3 25mm hose pipe connector. Slide the connector onto the end of the hose or pipe, making sure it is flush with the end.

25mm hose pipe connector. Slide the connector onto the end of the hose or pipe, making sure it is flush with the end.

25mm hose pipe connector. Slide the connector onto the end of the hose or pipe, making sure it is flush with the end.

25mm hose pipe connector. Slide the connector onto the end of the hose or pipe, making sure it is flush with the end.

. **New Hose Installation** Install the new hose following the manufacturer's instructions, ensuring a tight fit at all connections. Use thread sealant on the threads to prevent leaks.

. **New Hose Installation** Install the new hose following the manufacturer's instructions, ensuring a tight fit at all connections. Use thread sealant on the threads to prevent leaks.